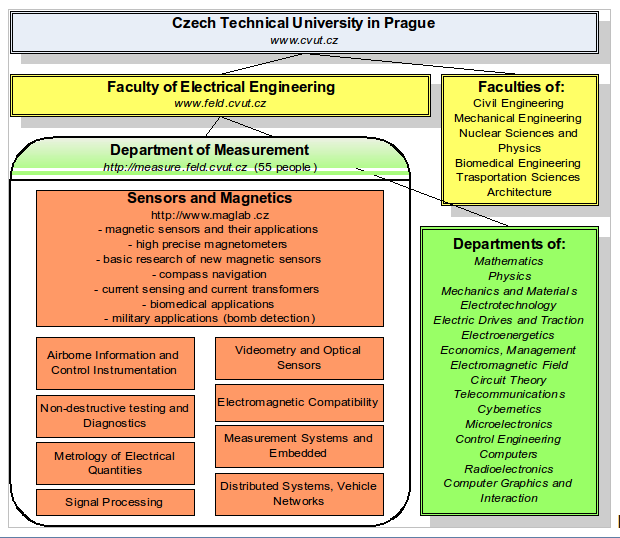

Department of Measurement – is one of the departments at the Czech Technical University in Prague. See Fig.1 which shows the main areas of our expertise. With respect to ISP-1 project almost all the areas mentioned in the chart are relevant (sensors, non-destructive testing, electromagnetic compatibility, measurement systems…)

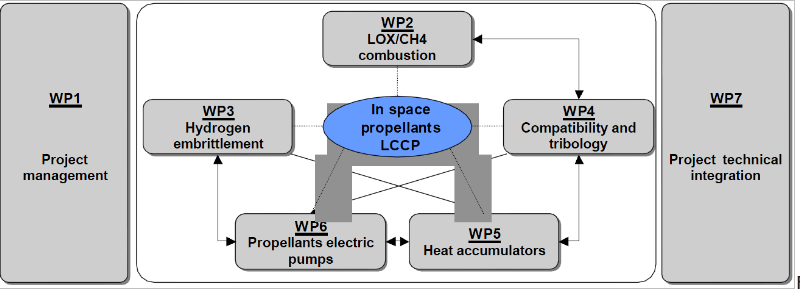

In Space Propulsion – 1 (ISP-1) – project within the Seventh Framework Program

Theme 9 – Space, Collaborative project. Started at September 2009, scheduled time-frame: 36 month.

The main goal of the project is to develop new technologies for cryogenic “In-Space” propulsion.

“In-space” means that the present project will not focus on access to

space, but rather deal with the propulsion systems needed in the

subsequent phases of space missions, once the spacecraft or upper stage

has already been placed in orbit (launcher upper stages, orbital

transfer or space exploration).

More

detailed information about the project scope brings Fig.2. There are

five main work-packages (LOX/CH4 combustion, material compatibility and

tribology, hydrogen embrittlement, heat accumulators and propellants

electric pumps) these are covered by technical integration and

management packages.

Department of

Measurement works within the “Propellants electric pump package”. The

leader of this work-package is Snecma (also responsible for hydraulic

pump design and technical integration). Polish company Mikroma is

responsible for an electric motor design and manufacturing. The final

prototype of the pump will be tested at the test bench which belongs to

University of Liege. Department of Measurement is responsible for design and delivery of measurement instrumentation for online diagnostics of the pump during testing.

Work package 6 – Department of Measurement: Instrumentation for the electric pump diagnostics

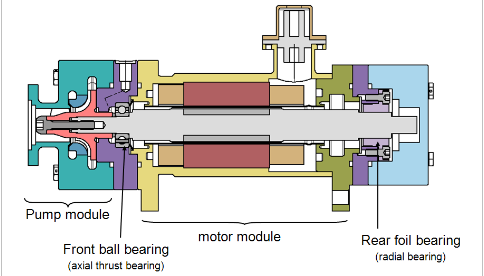

There

are some new technologies and technology integrations which are planned

to be tested. The propellant pumps were till now powered by turbine

(hot gases from other combustion chamber), the electric motor working at

high speed in cryogenic temperature range is the new element. Testing

of special bearings which are suitable for high speed cryogenic

operation is also one of the goals. Fig.3 should provide basic overview

over the electric pump construction (basically it is a cylinder with

approximately 70mm diameter and 200mm length).

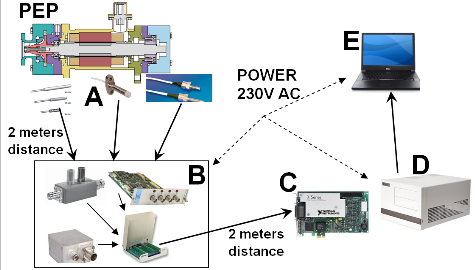

There is a wide range of sensors in the design in order to get as much information as possible from the testing. Sensors of vibration, temperature at various points, rotor shaft displacement, input – output pressure, speed of the motor. All the sensors are monitored during the testing and data logged for post-test diagnostics. The measurements are divided into two types –“low frequency” measurements (temperatures and some pressures) and “high frequency” measurements (vibrations, displacement, pressures, speed). The Department of Measurement is in charge of the “high frequency” measurements (but will also provide some low frequency sensors), while the low frequency measurements will reuse existing test bench instrumentation at ULg.

Fig. 4 shows the overall design of the high frequency instrumentation. The sensors are placed at desired points of the pump (A) and connected to signal conditioning unit with a signal concentrator (B). Output electric signals will be digitized using a commercially available Data Acquisition Card (C). The output data will be stored and processed using a dedicated computer system (with a real-time operating system) (D) and sent to the control room (E) in order to inform the operators if any problem occurs (increase in vibration value, higher displacement than allowed etc.). The challenge in this task is to select sensors capable of cryogenic operation (while keeping the costs at acceptable level), to test new sensors that are not approved yet. Of course the reliability of the system is extremely important because there are only two tests scheduled (the tests are generally unrepeatable).

ISP-1 project partners

1. Snecma S.A., France

2. ASTRIUM GmbH, Germany

3. AVIO S.P.A, Italy

4. Centre National d’Etudes Spatiales CNES, France

5. Deutsches Zentrum für Luft- und Raumfahrt EV DLR, Germany

6. Office National d’Etudes et de Recherches Aérospatiales ONERA, France

7. Université de Liège ULg, Belgium

8 Commission of the European Communities – Directorate General Joint Research Center, Belgium

9. Institut Supérieur de Mécanique de Paris ISMEP, France

10. Mikroma SA, Poland

11. Ceske Vysoke Uceni Technicke v Praze, Czech Republic

12. Universitat Politecnica de Catalunya UPC, Spain

13. Alcimed, France

14. Universita degli studi di Roma la Sapienza, Italy

15. Université de Poitiers LMS, France

16. SAS Bonatre, France

Contacts

Czech Technical University in Prague,

Faculty of Electrical Engineering,

Department of Measurement

Technicka 2, Praha 6, 16627

Czech Republic

https://meas.fel.cvut.cz/

Prof. Pavel Ripka

mail: ripka@fel.cvut.cz

phone: +420 224353945

fax: +420 233339929

Vojtech Petrucha (ISP-1 project manager)

mail: vojtech.petrucha@fel.cvut.cz

phone: +420 224353964

fax: +420 233339929